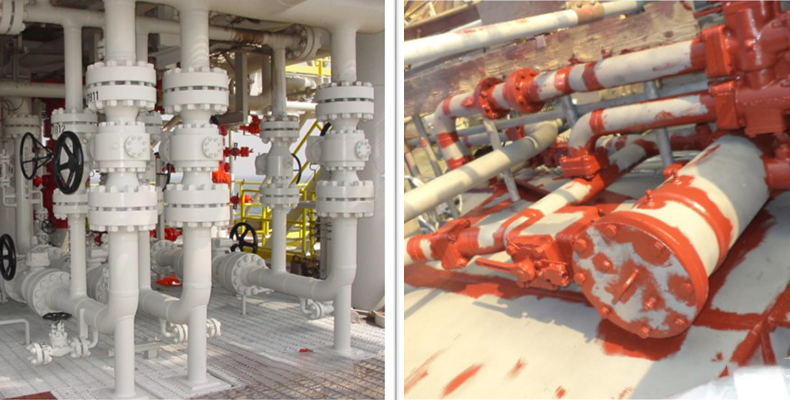

Cleaning and Painting of Structural Steel

Steel which is to be painted must be thoroughly cleaned of all loose mill scale, loose rust, dirt, and other foreign matter. Cleaning can be done by hand tool, power tool and a variety of levels of abrasive blasting. Abrasive blasting in most fabrication shops is done with centrifugal wheel blast units. The various surface preparations are described in specifications by the Society for Protective Coatings.

Unless the fabricator is otherwise directed, cleaning of structural steel is ordinarily done with a wire brush. Sophisticated paint systems require superior cleaning, usually abrasive blast cleaning and appropriate quality systems. Knowledge of the coating systems, equipment maintenance, surface preparation and quality control are all essential.

Gradual destruction of a metal or alloy by Chemical or electrochemical reaction.

Metals are in an unstable state.

Electrons travel from a negative area (anode) of the metal to a positive area (cathode) through an external conductive intermediate (electrolyte) and then returns to the anode through the metal itself to complete the corrosion cell.